Services

Cathodic protection (CP)

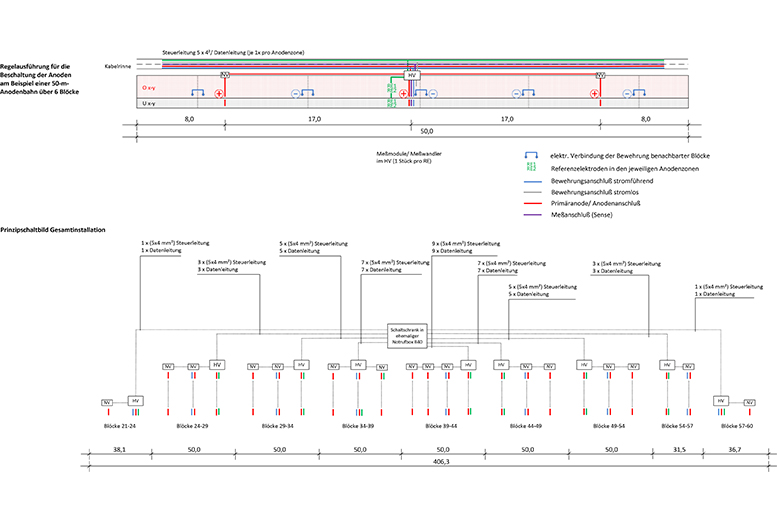

Cathodic protection of steel in concrete according to EN ISO 12696 is a procedure that protects the reinforcement durably from corrosion with the help of an additional anode. This way, chloride

containing, but undamaged concrete does not need to be replaced. The anodes consist either of activated titanium (Ti/MMO) and are operated by an external power source (impressed current CP)

or consist of zinc, which is a galvanic CP with a sacrificial anode. The permanent data surveillance provides information if the CP is working as intended. Impressed current CP systems can be adjusted if necessary. Zinc anodes can be used furthermore outside of ISO 12696 for local, unmanaged CP e.g. at patch repairs to suppress reversed corrosion on the edges of the repair areas (thus preventing the so-called “incipient anode” effect).

containing, but undamaged concrete does not need to be replaced. The anodes consist either of activated titanium (Ti/MMO) and are operated by an external power source (impressed current CP)

or consist of zinc, which is a galvanic CP with a sacrificial anode. The permanent data surveillance provides information if the CP is working as intended. Impressed current CP systems can be adjusted if necessary. Zinc anodes can be used furthermore outside of ISO 12696 for local, unmanaged CP e.g. at patch repairs to suppress reversed corrosion on the edges of the repair areas (thus preventing the so-called “incipient anode” effect).

The decisions about the application of a CP system and the choice of the anode system should be made after a thorough assessment of the structural conditions including the corrosion behaviour. Apart from services for consulting, design and surveillance of CP systems, we also conduct feasibility assessments, which is of interest especially for galvanic CP systems.