Procedures and tools

Here we would like to provide additional information about corrosion, corrosion measurement and rehabilitation as well as about our developments in this respect:

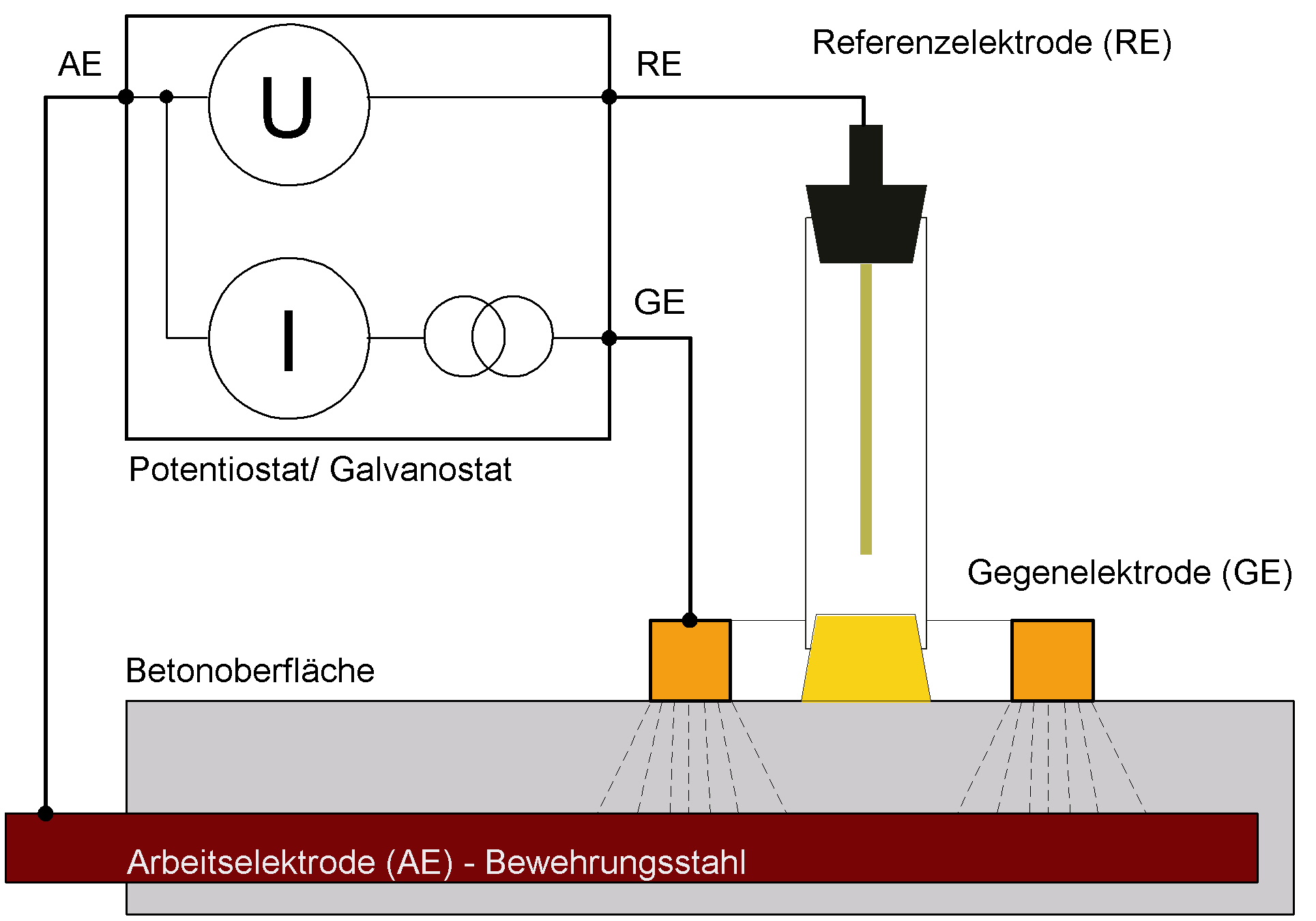

Enhanced electrochemical measurements with CITec CMS – corrosion measurement system

With the help of the CITec CMS the corrosion behaviour of steel in concrete can be assessed very precisely. Uncertainties arising from the stand-alone evaluation of just chloride or potential data can be avoided, and the corrosion related abilities of a concrete structure can be explored, understood and documented to a new, improved standard. This permits a tailor-made remediation and repair exactly for the needs of the structure, and helps to preserve it and keep the repair cost as low as possible. The Following questions can be answered reliably by using CMS methods:

- What is the conductivity of the concrete? (by AC impedance measurements)

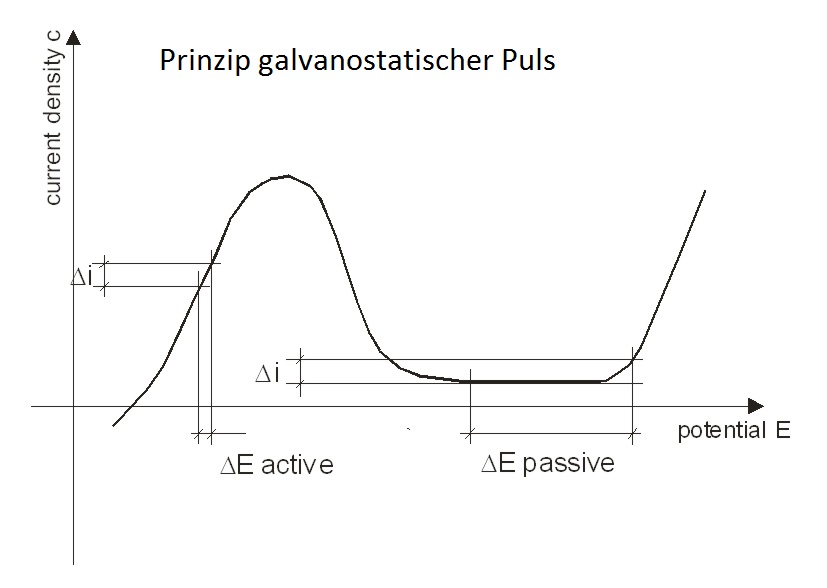

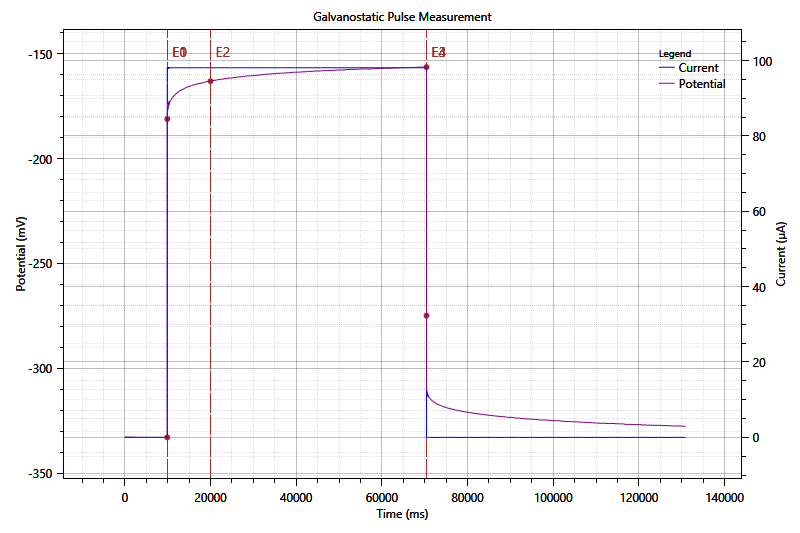

- Is the rebar surface passive, passive-like or active? (by galvanostatic pulse and linear polarization measurements)

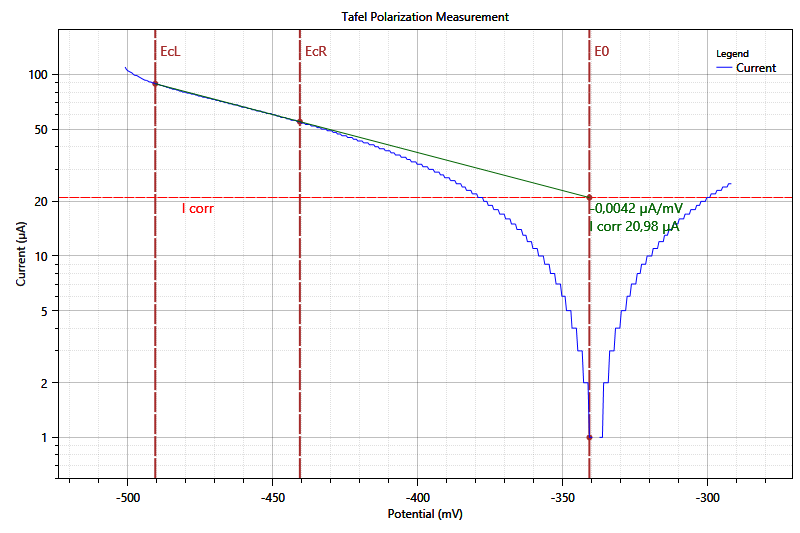

- How large is the corrosion activity at the moment of measurement – passive, moderate, high or very high? (by Tafel polarization, evaluation of possible corrosion current densities by referring to an assumed range of rebar surface polarized by the measurement)

- What is the chloride threshold applying to the individual structure/ structural part? This requires a representative amount of test locations and the comparison of the galvanostatic pulse curves with the chloride contents in the rebar vicinity.

The parameters electrolyte resistance RB, polarization resistance RP, total polarization resistance RP’, corrosion current at the rest potential Icorr as well as icorr min and icorr max (assumed from Icorr) can be calculated by the system automatically. The results can be verified on the measurement curves visually and can be corrected manually if necessary.

A very effective way of applying the CITec CMS is to run its measurements after the full-surface scan of potentials and surface resistivities: suspected corrosion spots and areas can be assessed quickly and non-destructively before deciding about taking dust samples for the analysis of chloride and water content or to inspect the reinforcement visually, which may be left to locations that have been proven to be corrosion active by the KMS results.

The CMS has been developed in a joint project of CITec with the Kurt-Schwabe-Institut für Meß- und Sensortechnik e.V. and Sensortechnik Meinsberg GmbH. The project was co-funded by the Sächsische Aufbaubank within the European Funds for Regional Development (ERFE).